Russian lathe accidents have become a growing concern in the manufacturing industry, posing significant risks to workers' safety and productivity. The increasing reliance on advanced machinery demands a deeper understanding of potential hazards associated with lathe operations. This article delves into the causes, statistics, and preventive measures to ensure workplace safety and compliance with industry standards.

As manufacturing processes evolve, the role of lathes in shaping and machining metals remains crucial. However, the complexity of these machines, especially Russian lathes, introduces unique challenges that require careful attention. Understanding the root causes of accidents and implementing effective safety protocols can significantly reduce workplace injuries.

This article aims to provide a comprehensive guide for manufacturers, engineers, and workers to enhance their knowledge about Russian lathe accidents. By analyzing real-world scenarios, exploring safety regulations, and offering practical solutions, we aim to create a safer working environment for everyone involved.

Read also:Unveiling My Desibuzz The Ultimate Guide To Your Favorite Platform

Table of Contents

- Introduction to Russian Lathe Accidents

- History and Development of Russian Lathes

- Common Causes of Russian Lathe Accidents

- Accident Statistics and Data Analysis

- Safety Protocols and Regulations

- Preventive Measures for Reducing Accidents

- Importance of Training and Education

- Regular Maintenance and Inspection

- Emerging Technologies for Enhanced Safety

- Future Trends in Lathe Safety

Introduction to Russian Lathe Accidents

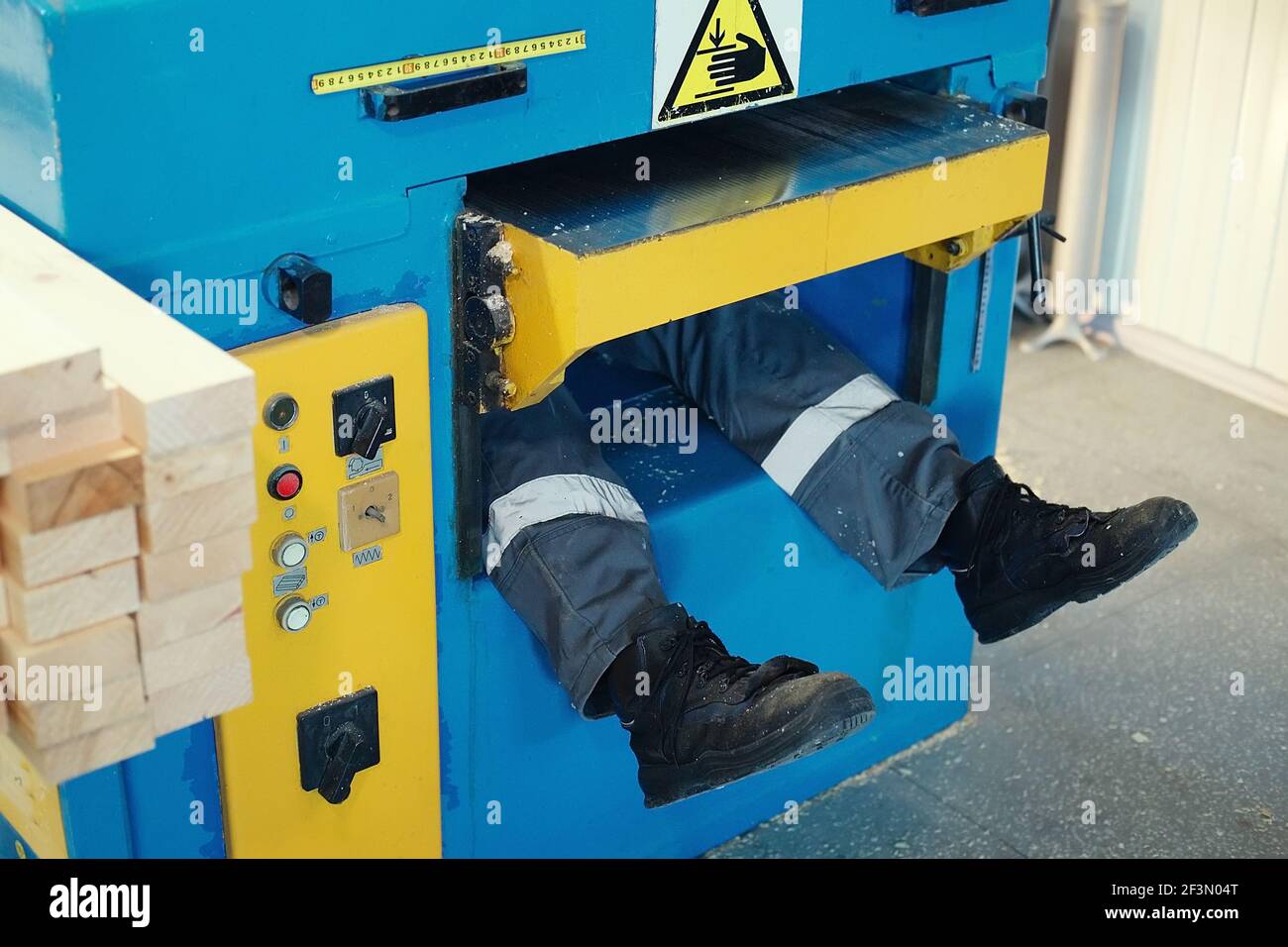

Russian lathe accidents are a critical issue that affects both small and large manufacturing facilities. These machines, known for their robust design and precision, can become hazardous if not operated correctly. The primary causes of accidents include human error, lack of training, and inadequate safety measures.

Manufacturing industries worldwide are increasingly focusing on improving safety standards to minimize the occurrence of accidents. Understanding the unique characteristics of Russian lathes and their potential risks is essential for creating a safer working environment. This section explores the basics of Russian lathes and their role in modern manufacturing.

History and Development of Russian Lathes

The development of Russian lathes dates back to the early 20th century, with significant advancements during the Soviet era. These machines were designed to meet the demands of heavy industrial applications, including aerospace, defense, and automotive sectors. Over the years, Russian lathes have evolved to incorporate modern technologies, improving their efficiency and precision.

Key Features of Russian Lathes

- Heavy-duty construction for durability

- High precision and accuracy in machining

- Customizable options for various applications

- Compatibility with advanced automation systems

Despite their advantages, Russian lathes require proper handling and maintenance to ensure safe operation. This section provides an overview of the historical development and key features of Russian lathes, highlighting their significance in the manufacturing industry.

Common Causes of Russian Lathe Accidents

Understanding the common causes of Russian lathe accidents is crucial for preventing them. These accidents often result from a combination of factors, including human error, machine malfunction, and inadequate safety measures. Below are some of the primary causes:

Human Error

Human error remains one of the leading causes of lathe accidents. Operators may overlook safety protocols, fail to wear personal protective equipment (PPE), or operate machines without proper training. These mistakes can lead to severe injuries and equipment damage.

Read also:Gladys Presley The Remarkable Life And Legacy Of Elvis Presleys Mother

Machine Malfunction

Regular wear and tear, lack of maintenance, and outdated components can cause Russian lathes to malfunction. These issues can result in unexpected movements, tool breakage, or other hazardous situations. Proper maintenance and timely upgrades are essential to prevent such incidents.

Inadequate Safety Measures

Insufficient safety measures, such as improper guarding, lack of emergency stop buttons, and inadequate ventilation, contribute to the occurrence of accidents. Implementing comprehensive safety protocols is vital for ensuring worker safety.

Accident Statistics and Data Analysis

Data from various industrial safety organizations reveal alarming statistics about Russian lathe accidents. According to the Occupational Safety and Health Administration (OSHA), approximately 8% of all machine-related injuries involve lathes. These accidents often result in severe injuries, including amputations, fractures, and burns.

A study conducted by the National Institute for Occupational Safety and Health (NIOSH) found that 60% of lathe accidents occur due to human error, while 30% are attributed to machine malfunctions. The remaining 10% are caused by environmental factors, such as poor lighting and inadequate workspace design.

Safety Protocols and Regulations

To mitigate the risks associated with Russian lathe accidents, industries must adhere to strict safety protocols and regulations. These guidelines are designed to ensure the safe operation of machines and protect workers from potential hazards.

Key Safety Protocols

- Wear appropriate PPE, including gloves, goggles, and hearing protection

- Follow machine-specific safety instructions and operating procedures

- Conduct regular inspections and maintenance checks

- Install proper guarding and emergency stop mechanisms

Regulatory bodies such as OSHA and ISO provide comprehensive guidelines for machine safety. Compliance with these standards is mandatory for all manufacturing facilities to ensure worker safety and avoid legal repercussions.

Preventive Measures for Reducing Accidents

Preventing Russian lathe accidents requires a proactive approach that involves training, maintenance, and technological advancements. Below are some effective preventive measures:

Training and Education

Providing comprehensive training programs for operators is essential for reducing accidents. Training should cover machine operation, safety protocols, and emergency procedures. Regular refresher courses and hands-on practice sessions can reinforce these skills.

Maintenance and Inspection

Regular maintenance and inspection of Russian lathes are crucial for identifying potential issues before they lead to accidents. Scheduling routine checks and addressing minor problems promptly can significantly enhance machine reliability and safety.

Importance of Training and Education

Training plays a vital role in preventing Russian lathe accidents. Operators must be well-versed in machine operation, safety procedures, and troubleshooting techniques. Educational programs should focus on both theoretical knowledge and practical skills to ensure comprehensive understanding.

Industries can benefit from partnering with certified training institutions and leveraging online resources to provide continuous learning opportunities for their workforce. This approach not only improves safety but also enhances productivity and efficiency.

Regular Maintenance and Inspection

Regular maintenance and inspection are critical components of a safe working environment. These processes involve checking machine components, lubricating moving parts, and replacing worn-out parts. A well-maintained machine operates more efficiently and poses fewer risks to operators.

Benefits of Regular Maintenance

- Reduces the likelihood of machine malfunctions

- Enhances machine performance and longevity

- Minimizes downtime and production delays

- Improves overall workplace safety

Implementing a preventive maintenance schedule can help identify potential issues early, allowing for timely repairs and replacements.

Emerging Technologies for Enhanced Safety

Advancements in technology offer innovative solutions for enhancing safety in Russian lathe operations. These technologies include automation, sensors, and machine learning algorithms that monitor machine performance and detect anomalies in real-time.

Automation and Sensors

Automated systems and sensors can monitor machine parameters such as temperature, vibration, and pressure. These systems can alert operators of potential issues before they escalate into accidents. Additionally, automation reduces the need for manual intervention, minimizing the risk of human error.

Machine Learning and AI

Machine learning algorithms can analyze large datasets to predict machine failures and optimize maintenance schedules. These technologies enable predictive maintenance, ensuring machines remain in optimal condition and reducing the likelihood of accidents.

Future Trends in Lathe Safety

The future of lathe safety lies in the integration of advanced technologies and innovative solutions. As industries continue to adopt Industry 4.0 principles, the focus will shift towards creating smart factories with enhanced safety features.

Emerging trends such as augmented reality (AR), virtual reality (VR), and Internet of Things (IoT) will play a significant role in improving safety standards. These technologies can provide immersive training experiences, real-time monitoring, and remote assistance, further reducing the risk of accidents.

Kesimpulan

Russian lathe accidents pose significant risks to workers and industries, necessitating a comprehensive approach to safety. By understanding the causes, implementing preventive measures, and adopting advanced technologies, manufacturers can create a safer working environment. Adhering to safety protocols, providing thorough training, and conducting regular maintenance are essential steps towards reducing accidents and enhancing productivity.

We encourage readers to share their experiences and insights in the comments section below. Additionally, feel free to explore other articles on our website for more information on industrial safety and best practices. Together, we can promote a culture of safety and innovation in the manufacturing industry.

References:

- Occupational Safety and Health Administration (OSHA)

- National Institute for Occupational Safety and Health (NIOSH)

- International Organization for Standardization (ISO)