Accidents in industrial environments, such as those involving Russian lathe machines, often capture significant attention due to their potential severity and the lessons they provide for workplace safety. The term "Russian lathe accident video" frequently surfaces online, highlighting incidents that emphasize the importance of proper training, adherence to safety protocols, and understanding machine operations. In this article, we will delve into the details of these accidents, their causes, and how they can be prevented.

Industrial machinery, including lathes, plays a crucial role in manufacturing processes worldwide. However, when mishandled or improperly maintained, these machines can lead to devastating accidents. Videos of such incidents not only serve as cautionary tales but also as educational resources for improving safety measures in workshops and factories.

This article aims to provide a thorough understanding of Russian lathe accidents, their implications, and preventive measures. By exploring real-life examples, expert insights, and actionable tips, we hope to empower readers with the knowledge needed to ensure safer working environments.

Read also:Nia Guzman And Chris Brown Story A Comprehensive Look At Their Journey

Table of Contents

- Introduction to Lathe Machines

- Overview of Russian Lathe Accidents

- Common Causes of Lathe Accidents

- Analysis of Russian Lathe Accident Videos

- Safety Protocols for Lathe Operators

- Preventing Future Accidents

- Expert Opinions and Insights

- Legal and Regulatory Aspects

- Impact on Industry and Workers

- Conclusion and Call to Action

Introduction to Lathe Machines

Lathe machines are versatile tools used in various industries for shaping metal, wood, or other materials. They operate by rotating the workpiece on its axis while applying cutting tools to achieve the desired shape. Russian lathe machines, in particular, have gained recognition for their robust design and functionality.

Understanding the basics of lathe operation is essential for anyone working in manufacturing or metalworking environments. These machines require precision, skill, and adherence to safety guidelines to ensure optimal performance and operator safety.

Key Features of Russian Lathe Machines

- Durable construction suitable for heavy-duty applications

- Precision engineering for accurate cuts

- Compatibility with a wide range of materials

- Adjustable settings for diverse projects

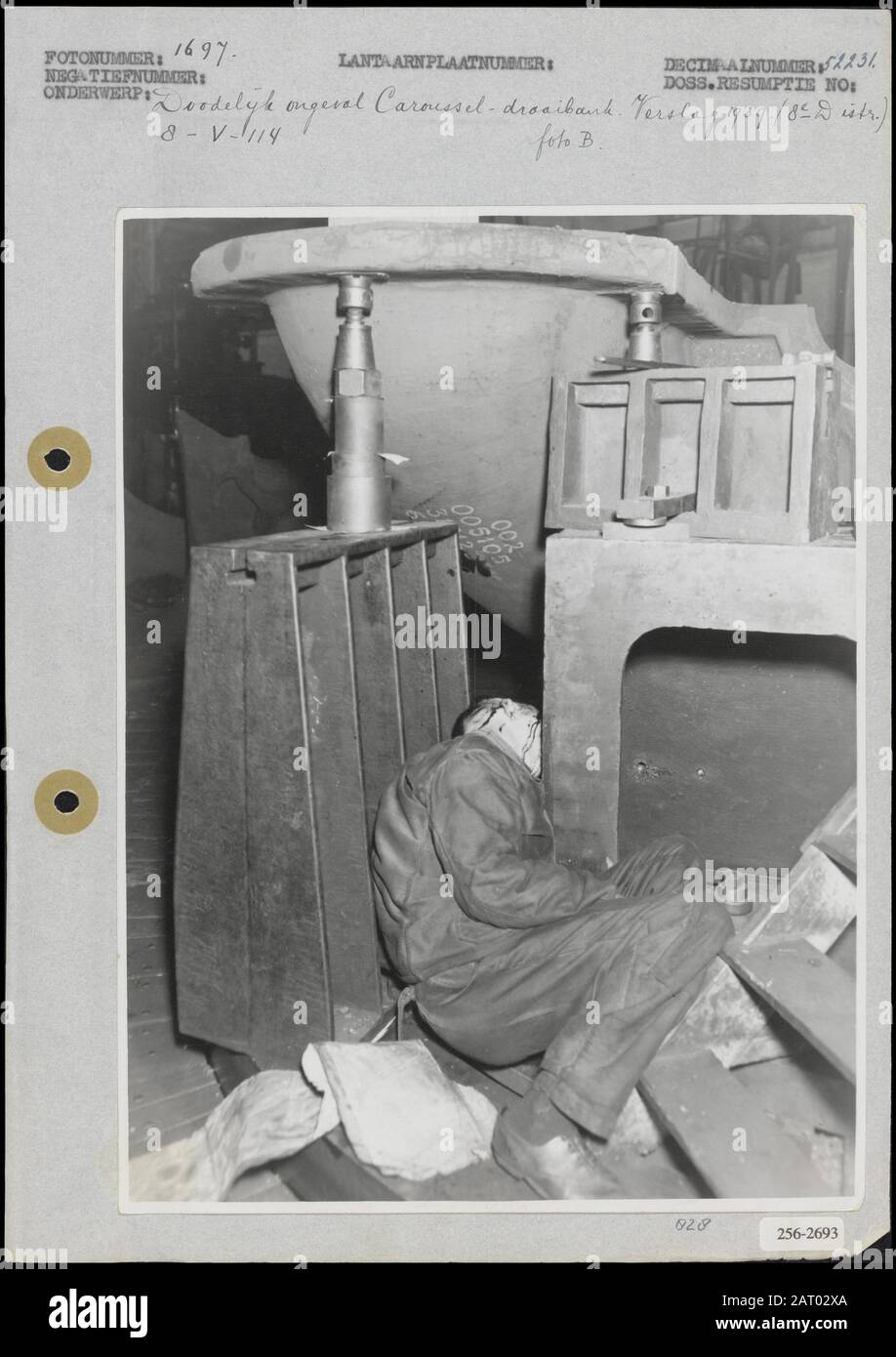

Overview of Russian Lathe Accidents

Accidents involving Russian lathe machines have been documented in various forms, including videos shared online. These incidents often occur due to a combination of factors, such as human error, lack of proper training, or machine malfunctions.

While these accidents can be alarming, they also serve as valuable learning opportunities for improving safety standards and operational practices.

Types of Accidents

- Cutting tool malfunctions

- Improper handling of materials

- Failure to use protective gear

- Inadequate machine maintenance

Common Causes of Lathe Accidents

Identifying the root causes of lathe accidents is crucial for preventing future incidents. Some common causes include:

- Lack of Training: Operators unfamiliar with machine operations are more prone to accidents.

- Inadequate Safety Measures: Failure to implement proper safety protocols increases the risk of injury.

- Machine Maintenance Issues: Neglecting regular maintenance can lead to unexpected malfunctions.

Addressing these issues through comprehensive training programs and regular equipment inspections can significantly reduce the likelihood of accidents.

Read also:Marisha Ray Health A Comprehensive Guide To Her Fitness Journey And Wellness Insights

Analysis of Russian Lathe Accident Videos

Russian lathe accident videos provide visual evidence of the dangers associated with improper machine usage. These videos often depict scenarios where operators fail to follow safety guidelines, leading to severe consequences.

Key Takeaways from Accident Videos

- Importance of wearing personal protective equipment (PPE)

- Need for regular machine inspections

- Value of proper training and certification

By analyzing these videos, manufacturers and operators can gain insights into potential hazards and develop strategies to mitigate them.

Safety Protocols for Lathe Operators

Implementing strict safety protocols is essential for ensuring the well-being of lathe operators. Some recommended practices include:

- Wearing appropriate PPE, such as goggles, gloves, and helmets

- Conducting pre-operation checks to ensure machine functionality

- Following manufacturer guidelines for machine usage

Training programs should emphasize the importance of these protocols and provide hands-on experience to reinforce learning.

Preventing Future Accidents

Prevention is key to reducing the incidence of lathe accidents. Employers and operators can take several steps to enhance safety:

- Invest in high-quality machinery and tools

- Encourage a culture of safety within the workplace

- Regularly update safety protocols based on industry standards

Collaboration between employers, operators, and regulatory bodies is vital for creating a safer working environment.

Expert Opinions and Insights

Industry experts stress the importance of continuous education and training in preventing lathe accidents. According to a study by the Occupational Safety and Health Administration (OSHA), comprehensive training programs can reduce workplace accidents by up to 40%.

Experts also recommend incorporating advanced technology, such as sensors and automated systems, to enhance machine safety and efficiency.

Legal and Regulatory Aspects

Legal frameworks and regulations play a crucial role in ensuring workplace safety. Employers must comply with standards set by organizations like OSHA and the International Labour Organization (ILO).

Failure to adhere to these regulations can result in fines, legal action, and damage to a company's reputation. Therefore, staying informed about regulatory requirements is essential for maintaining a safe and compliant workplace.

Impact on Industry and Workers

Lathe accidents not only affect individual workers but also have broader implications for the industry. Increased accident rates can lead to:

- Higher insurance costs

- Decreased productivity

- Reputational damage

By prioritizing safety, companies can protect their workforce and maintain operational efficiency.

Conclusion and Call to Action

Russian lathe accident videos serve as a stark reminder of the importance of safety in industrial environments. By understanding the causes of these accidents and implementing effective preventive measures, we can create safer workplaces for all.

We encourage readers to share this article, engage in discussions about workplace safety, and take proactive steps to enhance safety practices in their respective industries. Together, we can make a difference in reducing the incidence of lathe accidents and promoting a culture of safety.

References:

- Occupational Safety and Health Administration (OSHA)

- International Labour Organization (ILO)

- Industry research papers and case studies